Soft-Touch Beam Enhancement Resonator Technology

Soft-Touch Resonator Technology

As the range of complex laser welding applications increases, LaserStar’s research and development laboratory has continued its focus on accomplishing four major goals:

- Design the highest quality laser resonator cavity

- Produce a stable, clean, high-quality laser beam profile

- Accomplish consistent, pulse-to-pulse stability

- Optimize the laser beam shape to lower sensitivity to thermal lensing

High quality laser components (laser crystals, resonator reflectors, lens, lamps, etc.) continue to accomplish our goals. Nevertheless, thermal lensing still exists due to the nature and design of Nd:YAG laser welding systems.

Thermal lensing is common in high-power laser welding systems. The heating of the gain medium (peak energy) is hotter on the beam axis compared to the outer regions. Consequently, thermal lensing can often cause inconsistent results when applied to small, micro-welding applications.

LaserStar’s Soft-Touch™ Beam Enhancement Resonator Technology minimizes the impact of thermal lensing and greatly reduces the effects on the beam axis, producing an improved beam shape that can be focused to very small spot sizes while enhancing the overall laser weld quality.

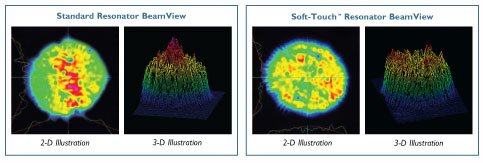

The following BeamView Analyzer illustrations demonstrate the benefits of Soft-Touch™ Technology.

(micro porosity, hollow parts, micro wire assembly, complex micro welding repairs, heat sensitive materials, etc.)

One can see from the Soft-Touch™ Technology image that a softer beam profile is generated, therefore greatly reducing the effects of the peak energy on the beam axis which often can splash metal, blow holes or damage heat-sensitive materials.

Soft-Touch™ Technology, combined with LaserStar’s other state-of-the-art features and benefits allow today’s laser welding operators to unleash the power of hot light, benefit from a comfortable, ergonomic design and ensure optimal platform technology.

Please review your specific application with a LaserStar Specialist to determine if the benefit of Soft-Touch™ Technology is

appropriate for your LaserStar laser welding system.

Soft-Touch™ Technology is an optional feature.